Adrian Facility

Also Known As: Bridgeport Brass Co., General Motors, Chevrolet Mfg. Div., National Distillers and Chemical Corp., Martin, A.C. Spark Plug

State: Michigan

Location: Adrian

Time Period: DOE May 25, 1954-1962; DOE (remediation) 1995

Facility Type: Department of Energy

Facility Description

Starting on May 25, 1954, the Bridgeport Brass Company had a contract with the Atomic Energy Commission (AEC) to operate the extrusion plant designated here as the Adrian Facility, which was located at 1450 E. Beecher Street in Adrian, Michigan. Bridgeport Brass operated a special metals extrusion press and produced uranium fuel elements for the Hanford and Savannah River Plant reactors and developmental extrusion work on thorium and depleted natural and slightly enriched uranium at the Adrian Facility.

After termination of AEC activities in 1961, most of this plant’s functions were transferred to Reactive Metals, Inc. (RMI) in Astabula, Ohio.Bridgeport shipped one large extrusion press to RMI and all other equipment was dismantled and scrapped. Decontamination and closeout work was accomplished in 1962, after the presses had been removed to Ohio.

Although this site was designated as part of the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1985, the only year in which remediation work took place, by or on behalf of the DOE, was 1995. The 1995 work was performed under the Bechtel National Inc. umbrella contract for DOE site environmental remediation.

Listing

Adrian Facility is listed as a Department of Energy (DOE) site inder the EEOICPA.

Site Description and History

The Adrian, Michigan, Site (formerly the General Motors Site) is located at 1450 E. Beecher Street, on the eastern side of Route 52 in Adrian, Michigan. The town of Adrian is approximately 20 miles southwest of Ann Arbor and 30 miles northwest of Toledo, Ohio. The site encompasses the former General Motors (GM) plant, a large complex covering approximately 17 acres.

During the 1950s, the previous owner of the site, the Bridgeport Brass Company, machined and shaped uranium metal under contract with the U.S. Atomic Energy Commission (AEC) for the fabrication of reactor fuel elements in the Hanford, Washington, and Savannah River, South Carolina, nuclear reactors. (The site was sold to Martin Marietta in the early 1960s and then to GM in 1974). At the end of the contract, the site was decontaminated to comply with radiological protection standards in effect at the time.

In 1977, Oak Ridge National Laboratory conducted a radiological survey at the site and identified residual uranium contamination in areas underneath the floor. Contaminant levels exceeded the current guidelines, and remediation was deemed necessary. The area that required remedial action comprises approximately 41,000 square feet of the plant.

During excavation for new construction at the site in 1985, additional contamination was identified in a tile drain line. The portion of the drain line directly under the manufacturing area was subsequently removed, placed in 55-gallon drums, and shipped to a U.S. Department of Energy (DOE) facility in Oak Ridge, Tennessee, for disposal. In addition, oil, scale, and sludge remaining in the pipe chase and oil collection system contained concentrations of uranium exceeding the current guidelines.

The Adrian site was designated for remedial action under the Formerly Utilized Sites Remedial Action Program (FUSRAP) in July 1988.

In 1994, DOE conducted a detailed radiological survey at the site. Results from that survey showed that the manholes, sumps, pipe chases, and associated piping were contaminated.

Decontamination at the Adrian site included a high-pressure water wash to remove water, oil, sludge, and scale from the sumps, manholes, and associated piping; pumping liquids into lined drums to remove oil/water and sludge; wiping the floors and walls to remove oil and scale; and excavating a 3-square-foot area.

Some materials with contamination that exceeded the guidelines were left in place in the piping system because of the high costs of complete remediation and the economic impact that would result from shutting down the GM plant to accomplish the remedial action. A hazard assessment concluded that contamination left in the piping system would not result in risk to the general public. Supplemental limits were approved for the contamination left in place. Supplemental limits may be applied in place of the primary limits established in DOE guidelines at locations where the cost of remediation would be unreasonably high compared to the long-term benefits, and the residual contamination does not pose a present or future risk to workers or members of the public.

Remedial action at the site was completed in July 1995.

*Source

Adrian Facility Workers

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

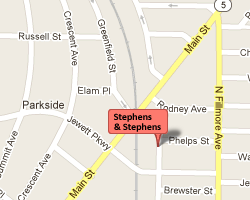

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

DOCUMENTS

NIOSH:

Technical Basis Documents

Share this:

EEOICPA CLAIMS

If you or your parent worked any of the DOE or AWE facilities listed on this website and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor.

Call EEOICPA Counsel Hugh Stephens at 1-800-548-4494, email hstephens@stephensstephens.com, or fill out the form below whether or not you have already filed a claim and even if your claim has been accepted or denied.

Contact Us

"*" indicates required fields

*note: Submission of this form does not establish an attorney-client privilege.

Contact Us

Address:

2495 Main Street, Suite 442

Buffalo, New York 14214

Phone:

(716) 852-7590

Fax:

(716) 852-7599

After Hours:

(716) 208-3525

Email Us:

R. William Stephens, Esq.

R. Hugh Stephens, Esq.

Lisa P. Neff, Esq.