Winchester Engineering And Analytical Center

Home / Areas of Practice / Energy Employees Occupational Illness Compensation Program Act (EEOICPA) / EEOICPA: SEC Sites By State / Winchester Engineering And Analytical Center

Also Known As: U.S. Public Health Service; N.E. Radiological Laboratory, Northeastern Radiological Health Laboratory, National Lead Co., AEC Raw Materials Development Laboratory

State: Massachusetts

Location: Winchester

Time Period: 1952-1961

Facility Type: Department of Energy

Facility Description

The Winchester Engineering and Analytical Center, built in 1952 under sponsorship of the AEC, was used to continue development of methods for extraction of uranium and thorium form ore and to prepare metal grade uranium tetrafluoride. Massachusetts Institute of Technology (MIT) began the work in 1946 at Cambridge, MA and continued the work after it was transferred later that year to Watertown Arsenal, Watertown, MA. American Cyanamid Company succeeded MIT in operating the project at Watertown Arsenal from 1951 until October 1952, when it was transferred to the Winchester Facility. In 1954, National Lead Company, Inc. took over operations under AEC contract AT(49-6)-924. Beginning in 1959, facility use shifted to laboratory testing of environmental analysis methods pertaining to uranium waste. In 1961, the work was discontinued, and the facility was transferred to the Department of Health, Education and Welfare (HEW) for use as a low-level environmental radiation surveillance laboratory and for analysis of radiopharmaceuticals. The facility is now run by the Food and Drug Administration.

CONTRACTORS: National Lead Company (1954-1961); American Cyanmid (1952-1954)

Listing

Winchester Engineering and Analytical Center is listed as a Department of Energy (DOE) site under the EEOICPA.

Special Exposure Cohort (SEC) Classes

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the Winchester Engineering and Analytical Center in Winchester, Massachusetts, from January 1, 1952, through December 31, 1961, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees in the Special Exposure Cohort.

(Note: This class was established from Petition 199)

Compensation

As of 08/10/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Winchester Engineering and Analytical Center is $450,000.

Winchester Engineering and Analytical Center Workers

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have filed a claim and even if your claim has already been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

Site Description

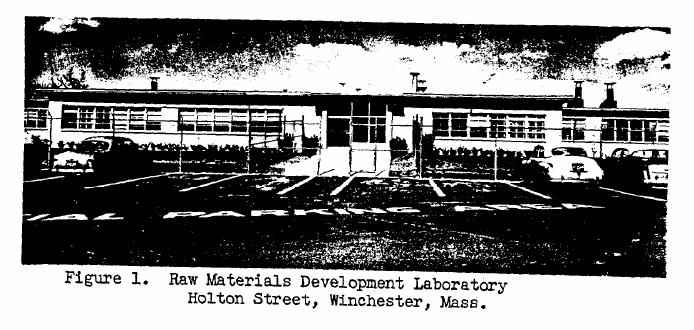

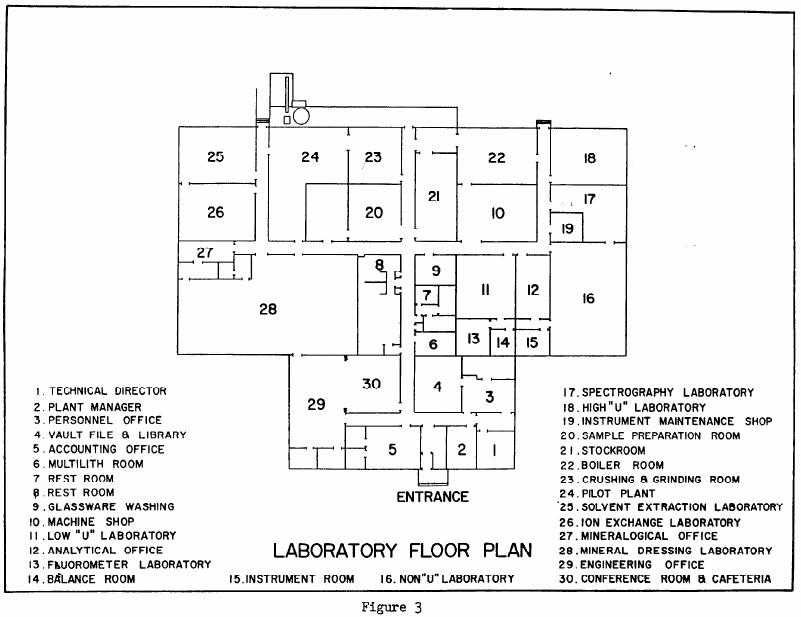

The research facilities of the Raw Materials Development Laboratory were located at Winchester, Massachusetts, a residential community about 15 miles from Boston. The laboratory building, constructed in 1952, is a modern, single-story, cement block and brick building with a floor area of 31,400 square feet (Figure 1). The building was divided into approximately thirty laboratories, work areas,shops and offices and was equipped and staffed for conducting awide variety of metallurgical, chemical and analytical investigations. Figure 3 shows a floor plan of the laboratory. A small test plant was available for continuous unit process testing. Well equipped machine and instrument shops provided for the maintenance and construction of standard and specialized equipment.

The laboratory was divided into three departments: Metallurgical, Chemical, and Analytical. The laboratory was equipped for investigations into acid and alkaline leaching techniques, ion exchange, solvent extraction, and precipitation processes. Facilities were also available for conducting mineralogical studies, flotation,gravity concentration, magnetic and electrostatic separations. A

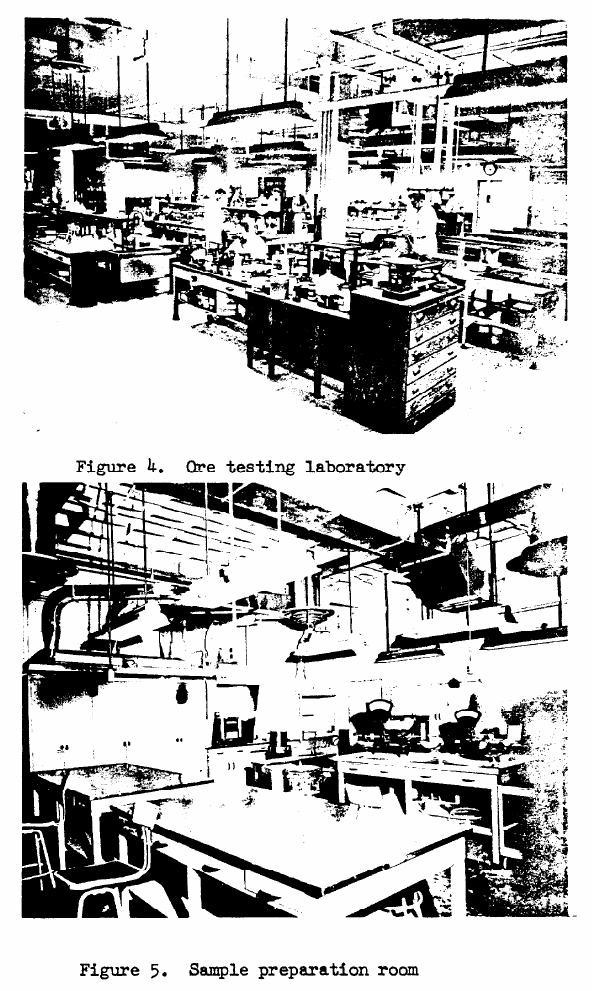

well equipped crushing and sampling laboratory assured careful preparation and sampling of the ores received for testing. Figure 4and 5 show the mineral dressing laboratory and the sample preparation room, respectively.

The analytical facilities contained besides the usual equipment for wet-chemical analyses a complete emission spectrograph laboratory,spectrophotometers and polarographs of both the recording and non-recording types, radiometric counting equipment, and other modern analytical instruments. Figures 6 through 9 show views of some of the chemical and analytical facilities.

DOCUMENTS

NIOSH SEC Petition Evaluation Reports:

Petition 199 (October 1, 1952 to December 31, 1961)

SEC Petition Evaluation Report, Petition SEC-00199, Rev #: 1

Report Submittal Date: May 30, 2012

SEC Petition Evaluation Report, Petition SEC-00199, Rev #: 0

Report Submittal Date: 04/24/2012

Share this:

EEOICPA CLAIMS

If you or your parent worked any of the DOE or AWE facilities listed on this website and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor.

Call EEOICPA Counsel Hugh Stephens at 1-800-548-4494, email hstephens@stephensstephens.com, or fill out the form below whether or not you have already filed a claim and even if your claim has been accepted or denied.

Contact Us

"*" indicates required fields

*note: Submission of this form does not establish an attorney-client privilege.

Contact Us

Address:

2495 Main Street, Suite 442

Buffalo, New York 14214

Phone:

(716) 852-7590

Fax:

(716) 852-7599

After Hours:

(716) 208-3525

Email Us:

R. William Stephens, Esq.

R. Hugh Stephens, Esq.

Lisa P. Neff, Esq.